To make the recycling process really effective, countless actions, interventions and technologies are required that involve individual citizens, local administrations, companies that manage sorting plants and, finally, the actual recycling plants.

Each of these actors is called upon to play its role to achieve a single final goal: to recover individual materials and transform them into secondary raw materials ready to be reintroduced into the production cycle. In this way, it is possible to protect the environment, avoid wasting natural resources and make the most of waste that otherwise would simply be incinerated or thrown into landfills.

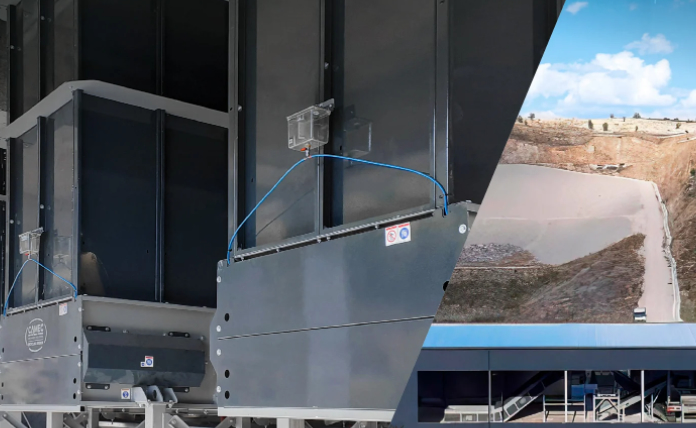

How a waste sorting plant works

Sorting plants are necessary to treat different types of waste, such as:

- The non-differentiated component of municipal solid waste (the so-called "dry” collected door to door or disposed of in the bins, but also the contents of road bins)

- Waste from multi-material separate collection (in Municipalities where different materials - for example glass, plastic and cans - are collected together)

In order for the separation process to be completed successfully, it is important that the material to be disposed of has already been correctly differentiated at the source, therefore that the undifferentiated component has already been reduced to a minimum and does not contain, as far as possible, recyclable materials. It is important that citizens are aware of this and are informed on the correct methods of waste separation applied in their municipality of residence, and that they change their habits accordingly.

If the separate collection allows to greatly reduce the amount of waste disposed of as "dry", it is still necessary to treat the fraction of unsorted waste in a professional manner. To do this, specific interventions are required which must be carried out in dedicated and appropriately organized selection plants.

Each sorting plant is a reality in itself, built in a personalized way to meet the needs of the individual territories, which vary both in terms of the quantity of waste to be treated and the quality of the materials that must be selected.

Sorting plants can use automatic or manual separation methods. These two systems in many cases coexist, because even the plants in which part of the separation activity is carried out automatically still have a final quality control phase carried out by hand, or intervention on specific waste with complex characteristics carried out manually by an operator. It is also possible that techniques for the automatic separation of a specific material (for example metal) are studied but that the differentiation of other waste is still carried out manually.

A sorting plant with manual separation is organized in such a way as to enable operators to operate as accurately as possible, and requires the waste to go through a series of successive steps:

- Arrival of bagged waste and loading of bags onto a conveyor belt

- Opening of waste bags, carried out by a lacerator or by a bag opener placed directly on the line. In this way, the waste is spread over the entire surface of the belt, to facilitate the selection activity

- Possible separation of some types of waste, carried out by automatic or mechanical means

- Loading of the waste on a second conveyor belt, which takes them to an elevated platform where the operators in charge of their manual separation are placed

- Manual separation of waste, carried out by specialized operators who remove specific materials from the undifferentiated mass. The waste removed from the belt is dropped into special containers placed under the platform

- Collection of the non-differentiable component, which remains on the conveyor belt and is unloaded to be sent to landfill or to the incinerator

- Compacting of the differentiated waste collected below the platform and sending them to specialized recycling centers

The advantages of manual separation

The main advantage of manual waste selection lies in the possibility of obtaining differentiated fractions of the highest quality. In fact, human intervention allows materials to be separated with great precision, without the need for machinery that uses advanced technologies. This allows on the one hand to send carefully selected materials for recycling, on the other hand it limits the risk that potentially dangerous materials for the environment and for humans - such as plastics, small household appliances tics or other waste that contain pollutants and which should not be disposed of unsortedly - are mistakenly incinerated.

Furthermore, the opening of a selection plant has positive employment and economic repercussions, because it allows the use of local labor, especially in countries where the path of differentiation is still in its infancy. This allows for the creation of a truly virtuous chain in the management of waste in the area and helps to create a mentality that is attentive to the environment and aware of the importance of proper waste treatment. This can result, also through appropriate information and communication campaigns, in an increase and improvement of domestic waste separation. in a more conscious management of special waste and, in perspective, in an ever greater ecological and environmental awareness.