Plastic recycling plants

Introduction: Plastic

Among the different symbols, established by the European Commission in 1997, used to distinguish the different types of material and to facilitate the separate collection, we find the triangle of arrows, a symbol that is placed on plastic packaging that means that the packaging is recyclable or that part of the material is recycled. Another form used is the hexagon, which indicates the material which the containers for liquid are made with.

The feature of this symbol consists in containing an abbreviation inside it: among the most frequent there are PET, PE, PP, PS and PVC, which indicate the various types of plastic and the relative container they have to be disposed. You can also find acronyms such as PI (which indicates coupled materials impossible to be separated during recycling phase, such as paper-plastic, plastic-aluminum, paper-aluminum, generally not recyclable).

What is the situation in Italy?

In the plastic recycling process, Italy plays an interesting and respectable role: the numbers are constantly growing as well as the benefits for the country. It is a thriving and constantly growing business, numerically speaking 2,600 companies, 33 sorting centers, 73 recycling plants, 35 preparers and users of waste fuels are involved.

All this, not to be forgotten, starts with the municipal administrations and citizens, who are the first ones to ensure that the process takes place in an optimal way. In the last years there have been great improvements, and in 2017 over 1 million tons of waste were collected separately (+ 11.7% compared to 2016).

The plastic recycling process

Is all plastic the same?

Obviously not, there are different types of plastic materials and they can be summarized in 3 macro categories:

- thermoplastics, or materials that acquire malleability with heat. From these materials you can form products that can be re-melted to give life to new products;

- thermosetting, unlike the former ones, are plastics that can be melted and molded, but once they have reached the solid state they cannot be melted a second time;

- elastomers, a class of copolymers (a polymeric mixture composed of a plastic and a rubber), which can be both thermoplastic and thermosetting, but characterized by great deformation and elasticity capacities.

Which rules govern the disposal and recycling of plastic materials?

To recycle plastic materials there is a need to comply with specific recycling codes, i.e. the international codes established by the European Commission in 1997, useful for the purpose of clearly recognizing what type of material was used for the object that is about to be made. to recycle.

On the national level, however, there is the UNIPLAST technical commission, acronym of Italian Body of Unification in Plastics, published a new standard in 2017: UNI 10667-1, a standard that regulates the recycling and recovery of plastic waste, as well as by-products. of plastics.

The new standard replaces and withdraws the older one, which dated back to 2010 (UNI 10667-1: 2010).

The commitment of associations in plastic recycling

There are six associations in the plastics supply chain that work with volunteers in line with the EU Plastic Strategy. The voluntary commitment, baptized as Circularity Platforms, is aimed at reaching a recycling target of at least 50% of plastic waste in Europe by 2040. This percentage increases up to 70% if we also consider plastic packaging.

The associations that have signed the agreement are Plastic Recyclers Europe (PRE), Petcore Europe, European Carpet and Rug Association (ECRA), Polyolefin Circularity Platform (PCEP Europe), European Plastics Converters (EuPC) and VinylPlus.

All plastic materials, once collected according to the regulations, are then pressed to be transported more easily to the plants that deal with the selection and recycling of plastic.

How does the plastic recycling process take place?

When the waste arrives at the collection point, is can be loose or packed. The first phase concerns the selection of waste, which travels on high-speed belts with large puffs of air that make a first selection, separating light wrappers from the heaviest ones. A mechanical sorting takes place, introducing the materials into a rotating screen (a sort of huge centrifuge) which separates the families of plastics according to their size. Optical readers then intervene and make a second separation based on the polymers present in the product to be recycled and on any colours, thanks to the air blow mentioned above.

In a second phase, on the other hand, workers manually sort a small part that the machines cannot automatically separate.

After the manual removal of any possible unsuitable plastic materials, the materials are ready to pass under a press that will generate packaging of different colours. In the case of PET, for example, it differs according to 3 different colors: colored, light blue, transparent. In addition to these, high-intensity polyethylene (mainly given by detergent drums and related bottles) and low-density polyethylene (obtained from various shopping bags and shoppers) also end up in the press.

The packaging recycling chain moves through the codification of the polymers present in the product to be recycled: among the recyclable plastics, it is also possible to identify different kinds of films, processing waste (also called sprues), mixed plastics, bumpers and tanks, big bags raffia, coupled plastics and plastic containers.

At the end of the process, it is normal that a plastic part is not recyclable, and therefore constitutes the waste material that cannot be used. The main reason is due to errors made in the waste disposal phase, materials that are incorrectly included in the plastic collection or that have not been unpacked before being thrown away.

The unusable waste ends up in the waste-to-energy plants and will form the basis for energy recovery.

At the end of the separation phase, we move on to the real recycling plant: the waste passes into an enormous washing machine that takes care of washing, separating, spinning and grinding the plastics, reducing it into chips and flakes.

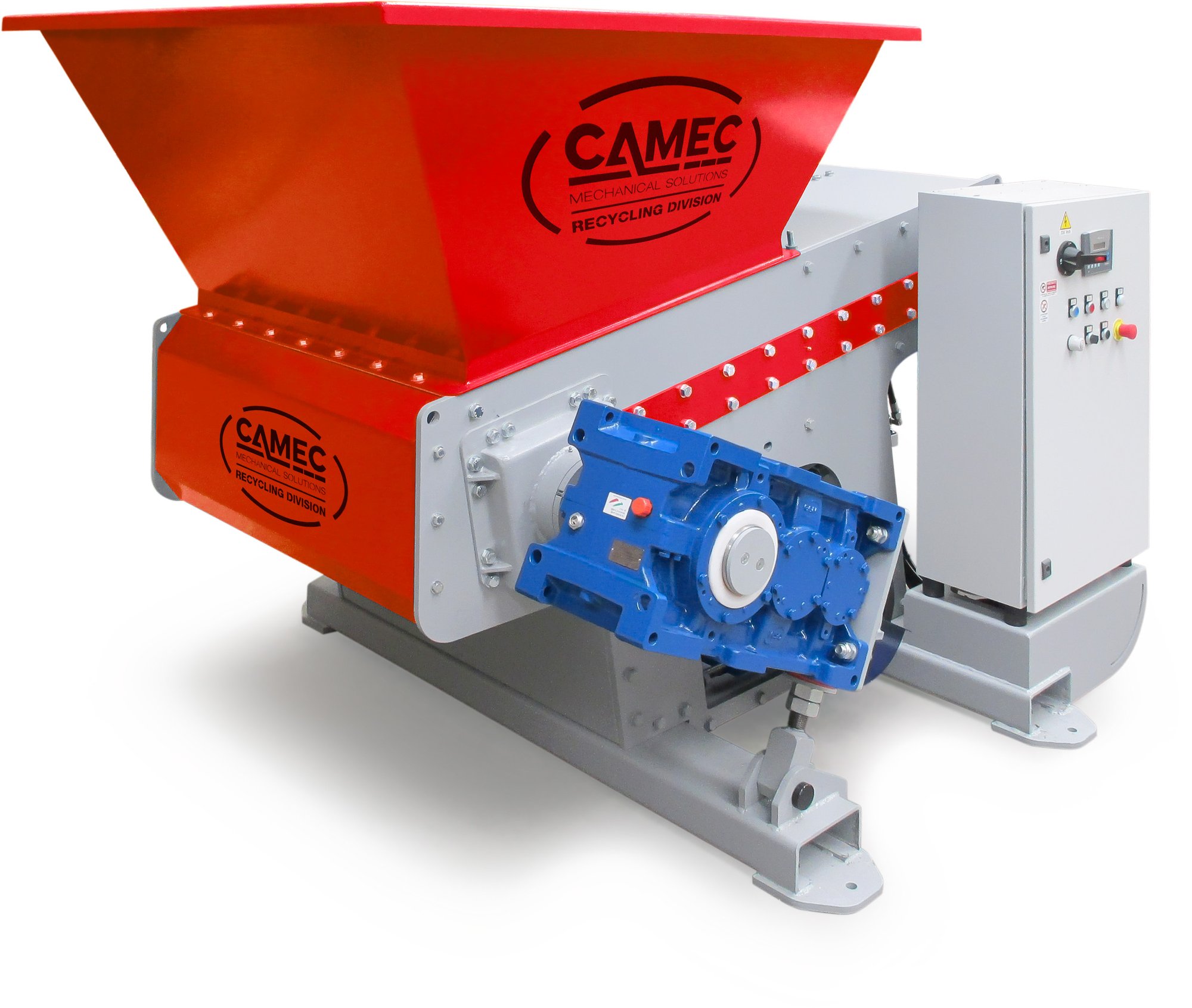

The plant models for plastic shredding

There are different models of plastic shredding plants, depending on the type of waste, urban or industrial, and of granulators, whether combined or in line.

From single-shaft industrial grinders to double-shaft and four-shaft industrial shredders, there are plants suitable for grinding products with a high specific weight.

Various standards establish severe impositions in terms of granulometry and cleaning of the ….: the granulometry depends on the degree of purity of the granule that will be processed. Based on the application of the MPS material (Secondary Raw Material, a new product deriving from recycled raw material), it is possible to get a variable degree of purity of the granule, depending on the flexibility of the plant that will process the material.

There are also more advanced systems that are able to treat also PET, the noblest of the plastic materials.

Il Trituratore Monorotore – GR280

Are there any recycling plants that can be built upon customer request?

Depending on the needs of each customer, it is possible to request a recycling plant at a good market price, intervening on components such as the degree of purity of the granule which can vary according to the application of the MPS material.

The benefits of plastic recycling

What products can we make from recycled plastic?

Recycled materials can give life to an almost infinite number of new products, for many categories of objects that can be found in everyday life.

From sweaters, glasses, fleece sweaters, different types of clothing, wrappers, chairs, shopping bags and vases.

Recycled products can be many, but the benefits?

According to the "Green economy report", developed by Corepla, the national consortium for the collection, recycling and recovery of plastic packaging, in 2017, 43.4% of the packaging collected was sent for recycling, resulting in an economic benefit of approximately 2 billion euros in the country for the raw material not consumed, for the production of energy and for the saving of CO2 emissions.

In Italy there are about 40 plants for the selection of plastic materials to be recycled, which in this sense contribute to closing the productivity cycle and giving new life to important quantities of waste.

In this way we try, therefore, to emulate the cycle of nature, in which everything is transformed and reused, making waste a new resource.

The reduction in the volumes of unsorted waste is also a benefit deriving from the recycling of plastic materials: man's ecological footprint must necessarily be regulated and kept under control over the years, with an eye to the near future.

In addition to the benefits for the environment and for everyone's life, less positive characteristics are also to be reported: the pollution of dust in the atmosphere, in fact, returned by the waste incineration processes, is constantly monitored to ensure that the limits are not exceeded.

According to EU directives, in fact, there are limitations on emissions into the atmosphere of pollutants originating from medium combustion plants. For medium combustion plants we mean plants that have a nominal thermal power equal to or greater than 1MW and less than 5MW, regardless of the type of fuel used.

Appendix: plastics and sea pollution

Does the waste also extend along the coasts?

Another issue as topical as it is problematic concerns the disposal of waste in the sea that inevitably ends up along our coasts.

Currently, if all the salty waters of the world were filtered, it would be found that every square kilometer of it contains about 46 thousand suspended micro particles of plastic.

These are huge and equally worrying numbers, both for the animal ecosystem and for the inevitable repercussions on the food chain, whose damage is currently underway.

Over the years, the use of plastic has undergone a significant increase by the most disparate companies, and this material has become one of the symbols of industrial development, along with concrete and steel.

The downside is of course given by the characteristics of this product which, if not recycled properly or sent to special incinerators, ends up in the environment, favoring the alteration of ecosystems.

How much plastic ends up in the seas?

Every year, the plastic produced in the world varies from 4 to 12 million tons and is the cause of 80% of marine pollution, due to plastic waste that enters the sea pushed by the wind or dragged by urban drains and river courses.

Ships that sail the seas also produce a part of waste, such as fishing boats, merchant ships and tourist boats of all kinds.

The Pacific Ocean can unfortunately boast the presence of a plastic island comparable to the size of the United States.

The Mediterranean Sea?

Even in the Mediterranean Sea, pollution due to the presence of plastic material is a current problem. But where are the greatest concentrations of waste in our sea? A study conducted by the CNR speaks of a very high concentration of waste between Tuscany and Corsica, highlighting the presence of a square kilometer of plastic waste in the northern Tyrrhenian Sea, for a total of about 10 kilos of waste.

In large part, the waste found in the sea consists of what is disposed of by households in everyday life.

Is it possible to reduce marine pollution?

Among the many methods useful for reducing marine pollution, concrete help can come from the adoption of behaviors aimed at reducing both the consumption of plastic and the production of waste deriving from plastic materials.

The first behavior to adopt is to reduce the use of plastic bags (shoppers), since according to a recent report by the European Commission, the average number of shoppers used in a year is around 300 per person, for the production of which they are used. 910,000 tons of oil that emit 8 kg of CO2 per family into the air.

In general, careful separate collection is the main advice to start from. It is also recommended:

- reduce the use of disposable bags and use recyclable ones;

- prefer the use of draft products rather than packaged with, at times, an excessive number of packaging;

- make sure that the plastic bags used for separate collection are actually made of biodegradable material.

Tell us about your project

We supply the best technical solutions for your requirements