Industrial Tippers for Bins

The special feature of our tippers is in the electro-welded tubular iron structure with a mesh-enclosed cage. Another very popular feature of Camec machines is their perfectly vertical elevation at any height, which allows an extremely small overall footprint.

Always ready to listening to customers’ needs, Camec can easily customise the standard version of its machines with tailor-made designs to suit particular working environments. Regardless of their configuration, Camec tippers are highly reliable machines that are easy to maintain, with a special focus on safety.

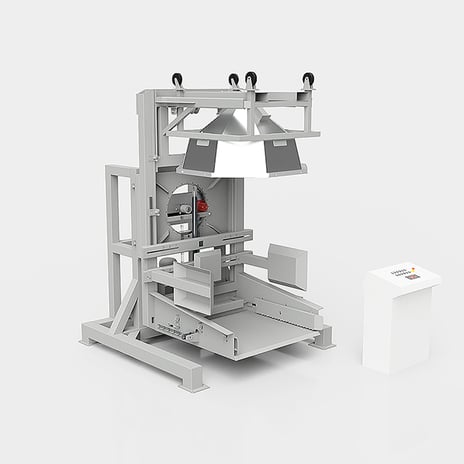

Front Discharge Single Tippers

Ideal to meet all requirements for tipping medium-sized bins containing items that cannot be deteriorated. Bin unloading on the front side opposite the loading side.

- Electric-pneumatic operation

- Chain lifting transmission

- Bin locking grippers

- Bin locking bar

- Pneumatic valve for bin locking

- Door retainer timed micron

- Pneumatic-electric safety valve

- Air connection: 90° connection for Rilsan hose diam. 8

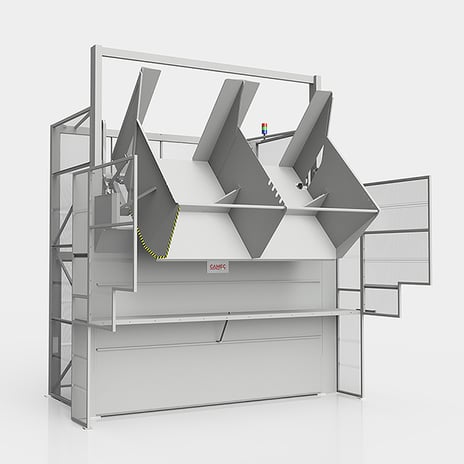

Front Discharge Double Tippers

These tippers are required for particularly heavy-duty work cycles.

Ideal to meet all requirements for tipping medium-sized bins containing items that cannot be deteriorated.

- Electric-pneumatic operation

- Chain lifting transmission

- Bin locking grippers

- Bin locking bar

- Pneumatic valve for bin locking

- Door retainer timed micron

- Pneumatic-electric safety valve

- Air connection: 90° connection for Rilsan hose diam. 8

Side Discharge Tippers

Camec offers a special solution for confined spaces with machines that discharge laterally (right or left) to the loading side.

- Electric-pneumatic operation

- Chain lifting transmission

- Bin locking grippers

- Bin locking bar

- Pneumatic valve for bin locking

- Door retainer timed micron

- Pneumatic-electric safety valve

- Air connection: 90° connection for Rilsan hose diam. 8

Tippers with Stainless Steel Coating for Food Use

System with stainless steel coating only on the internal parts of the trolley in contact with the material or made entirely from stainless steel for food use.

- Electric-pneumatic operation

- Chain lifting transmission

- Bin locking grippers

- Bin locking bar

- Pneumatic valve for bin locking

- Door retainer timed micron

- Pneumatic-electric safety valve

- Air connection: 90° connection for Rilsan hose diam. 8

Tippers with Discharge Dosing Systems

Specific application with vibrating conveyor or vibrating screen used for cleaning the material from dust or chips and for better distribution of the material.

- Electric-pneumatic operation

- Chain lifting transmission

- Bin locking grippers

- Bin locking bar

- Pneumatic valve for bin locking

- Door retainer timed micron

- Pneumatic-electric safety valve

- Air connection: 90° connection for Rilsan hose diam. 8

Tippers with Metal Detector

This solution is used when the spilled plastic material needs an extraction of polluting ferrous and non-ferrous metal material.

- Electric-pneumatic operation

- Chain lifting transmission

- Bin locking grippers

- Bin locking bar

- Pneumatic valve for bin locking

- Door retainer timed micron

- Pneumatic-electric safety valve

- Air connection: 90° connection for Rilsan hose diam. 8