Industrial Tippers for Special Applications

Custom design means that each tipper is created to meet the specific needs of the customer, taking into account factors such as the type of material to be tipped, bin sizes, production flows and any other special requirements. This approach ensures that the tipper is integrated seamlessly into the existing production process, thus maximising efficiency and productivity.

Front Discharge Tippers in PET/YOGHURT Shredding Plant

Combined and integrated solution with front discharge tipper and GRR280 single-shaft shredder for handling and shredding plastic pots containing yoghurt.

Front Discharge Tippers in Aluminium Shredding Plant

Combined and integrated solution with front discharge tipper and GSR480 single-shaft shredder for handling and shredding aluminium chips.

Front Discharge Tippers for Preforms with Special Conveying Hopper

Front discharge tipper for preforms with special conveying hopper.

Trolley-mounted Tippers

A trolley-mounted system that allows the tipper to be moved if the tipping process needs to be carried out in different areas of the factory.

- Electric-pneumatic operation.

- Chain lifting transmission.

- Bin locking grippers.

- Bin locking bar.

- Pneumatic valve for bin locking.

- Door retainer timed micron.

- Pneumatic-electric safety valve.

- Air connection: 90° connection for Rilsan hose diam. 8.

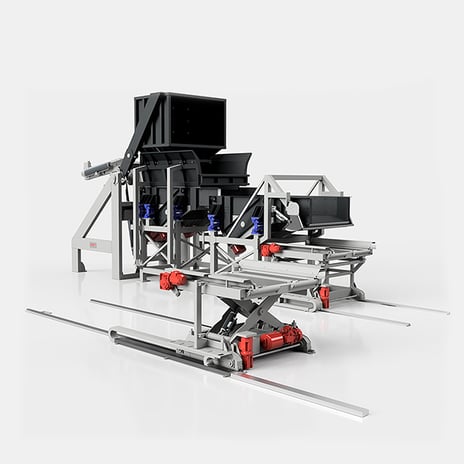

Tippers with Automated Loading System

System for lifting/tipping and dosing of materials for hardening treatment.

Frontal Tipper with Special Loading Height

Tipper with entry gate height in special configuration.

- Electric-pneumatic operation.

- Chain lifting transmission.

- Bin locking grippers.

- Bin locking bar.

- Pneumatic valve for bin locking.

- Door retainer timed micron.

- Pneumatic-electric safety valve.

- Air connection: 90° connection for Rilsan hose diam. 8.