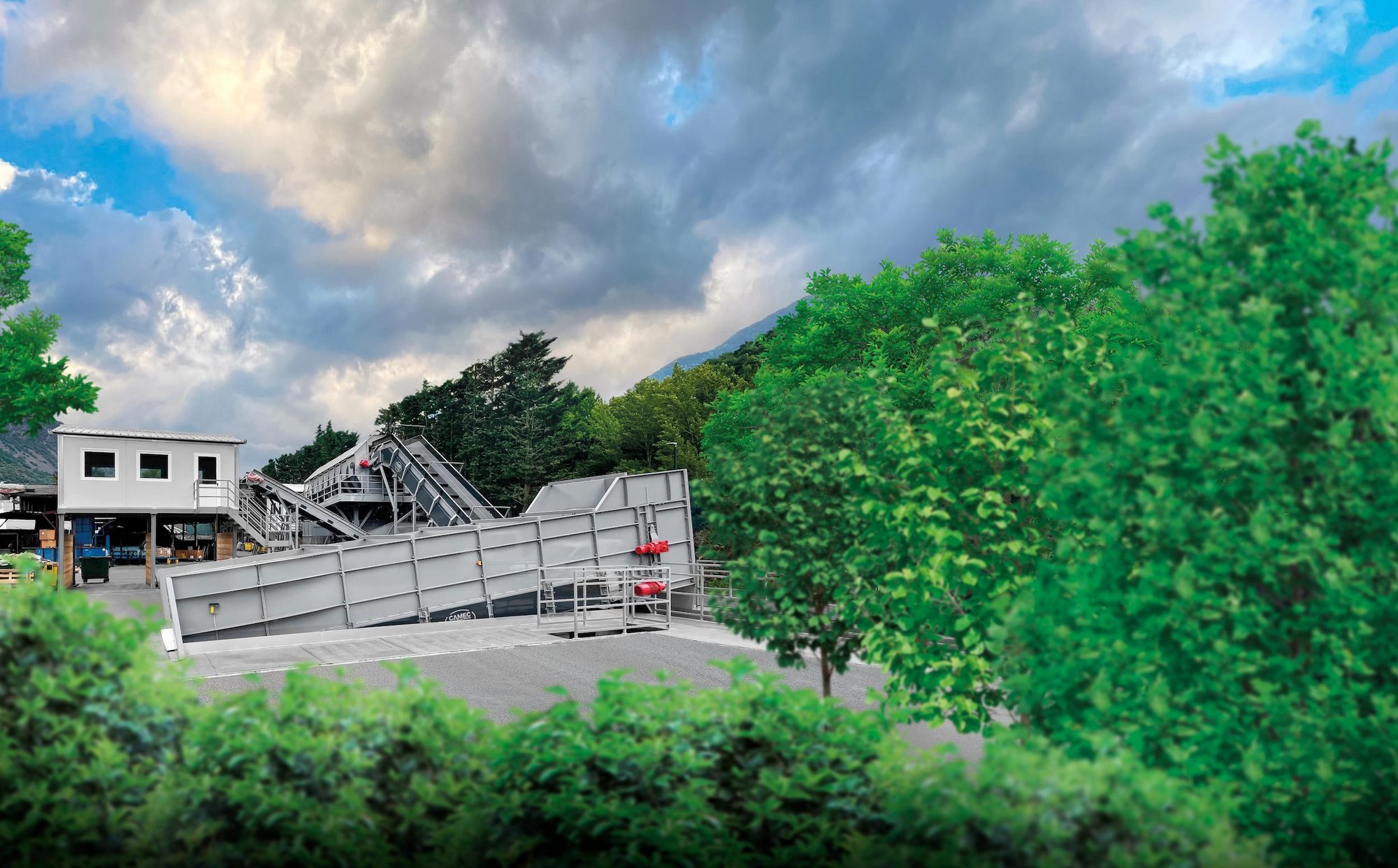

CAMEC's customized solutions for waste treatment and recovery

CAMEC: technologies and solutions for waste recovery

For 32 years, CAMEC has been designing and building machinery and turnkey recycling plants, supporting companies and public and private entities in managing waste efficiently, safely, and in compliance with national and European regulations.

The extensive experience gained by CAMEC's technicians in designing and implementing customized and turnkey plants allows us today to offer tailor-made solutions designed for the treatment of every type of waste, from municipal solid waste to medical waste, from bulky materials to ferrous metals, including WEEE, industrial waste, and many others.

Every CAMEC plant is born from identifying the most suitable engineering solutions to meet our customers' needs, and every stage of the waste treatment process is designed to combine efficiency, automation, reliability, and safety.

In this way, every CAMEC plant is able to guarantee the best possible recovery of different types of waste, maximizing the amount of material recovered and sent for recycling, in compliance with regulations and the principles of the circular economy.

Plants for the management of Municipal Solid Waste (MSW)

CAMEC offers tailor-made solutions to all companies active in the recycling sector and to Public Administrations involved in the correct management of Municipal Solid Waste, a category that includes - in addition to common household waste - also that from offices, green areas, commercial and light industrial activities. The treatment of this type of waste requires managing a wide variety of different materials, and requires administrations to equip themselves with tools capable of guaranteeing flexibility and efficiency, with the aim of optimizing separation activities and therefore recovering the largest possible amount of recyclable material.

All CAMEC lines for the treatment of Municipal Solid Waste are designed starting from our customers' needs and their technical and logistical requirements, evaluating the availability of space within their plants and always taking into consideration the importance of guaranteeing optimal working conditions and a very high level of safety for operators.

The MSW treatment process is divided into a series of successive and coordinated phases, which normally begin with the opening of the bags containing the waste and their loading onto the line. This first step, which is carried out automatically using special shredders or bag openers, allows for easier access to the mass of waste to be processed and facilitates the subsequent screening activities, which can be carried out automatically or manually, through the intervention of operators who separate the different recyclable materials. The material recovered through these selection activities, once correctly sorted, is then stored in special bunkers and subsequently pressed into compact bales, which reduce its volume and simplify the sending of the different types of material to the recycling plants.

The type of machinery integrated into the Municipal Solid Waste selection plant and the engineering solutions implemented vary according to the customers' needs, but all CAMEC lines are developed to increase the level of automation as much as possible, in order to reduce the need for human intervention as much as possible and increase operator safety. In addition, the modular design of the plants allows for the most efficient integration of the different machines used in the line, optimizing spaces and offering customers truly tailor-made solutions. The result is an efficient system that maximizes the amount of recovered materials and reduces the fraction of non-recoverable waste destined for landfill.

The safe treatment of hazardous medical waste with Sterilmix 250

CAMEC develops innovative solutions for the treatment of hazardous medical waste produced both in hospital environments and in private medical practices, clinics, nursing homes, or veterinary laboratories. According to the provisions of DPR 254/2003, in fact, medical waste and special waste that, given their characteristics, are similar to hazardous infectious waste must be managed in compliance with specific regulations, to ensure the safety of those who handle their disposal and to avoid any possible risk of contamination.

Equipping oneself with tools developed and patented specifically to guarantee the highest levels of safety is essential for entities that must treat this type of waste, and for this very reason, CAMEC has designed Sterilmix 250, an integrated machine that combines shredding and sterilization functions in a single unit.

Thanks to Sterilmix 250, it is possible to reduce the size of hazardous medical waste and sanitize the material using a single tool that performs a fully automated work cycle. The waste is loaded into the machine through a direct tipping system, shredded by double grinding rollers, and then conveyed into a hermetic stainless steel screw conveyor, which transfers it to the sterilization chamber. Here, the heat generated by special electric heaters raises the internal temperature to the levels necessary for complete sanitization. At the end of the cycle, the waste is transformed into inert material, classifiable as assimilable municipal waste (EWC 200301) and ready for disposal.

This technology provides significant advantages in terms of protecting the health of the community and the operators involved in waste disposal, who, thanks to the complete automation of the process, do not have to handle the material at any stage of the treatment, and it also allows for significant cost savings. Thanks to Sterilmix 250, in fact, medical waste can be sanitized directly within the facility that produces it, thus cutting transportation costs and limiting the risks of environmental contamination associated with the road transport of potentially contaminated and unsterilized material. Furthermore, the thorough shredding of the material makes it possible to reduce the volume of waste to be disposed of by 75%, further reducing the costs for its disposal in landfills or incinerators.

Power and reliability for treating bulky waste with the GL900/35 shredder

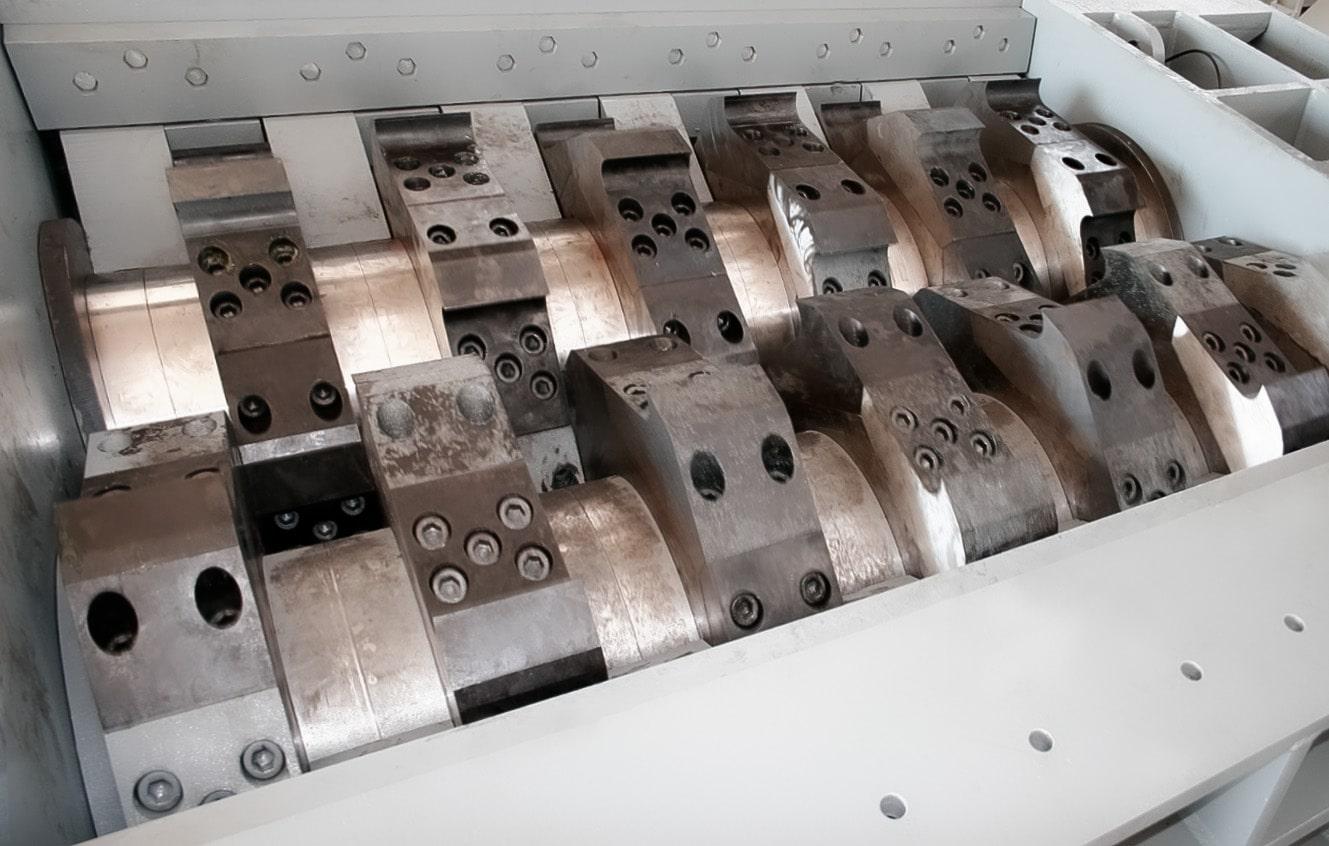

Treating bulky waste requires the use of high-powered machinery capable of quickly and effectively shredding complex and voluminous waste: this is precisely why CAMEC has developed solutions like the GL900/35 shredder, a single-shaft shredder with a hydraulic drive capable of ensuring high performance and operational continuity even when processing bulky scraps such as mattresses, sofas, rigid plastic, rubber, or WEEE urban and industrial waste.

The heart of the GL900/35 shredder is a 3500-millimeter rotor equipped with hardened steel blades and Hardox500 counter-blades, powered by two 200 kW electric motors each, connected to a high-performance hydraulic transmission. This configuration allows it to achieve a total installed power of 400 kW, enabling the shredder to process up to 25 tons of material per hour.

The GL900/35 is equipped with a PLC control system with a touchscreen interface, which allows for real-time monitoring (even remotely) of the machine's operating parameters, activation of preset shredding recipes, and automated management of the treatment of different types of waste. Furthermore, the shredder integrates self-diagnostics, remote diagnostics, and predictive maintenance features and can be equipped with maintenance compartments with automatic opening and advanced safety systems, allowing for easy interventions on the machine when necessary.

Thanks to these features, CAMEC's G900/35 is able to guarantee the highest levels of safety and reliability, even when faced with the need to treat complex and voluminous waste. In addition, the shredder's compact and modular structure allows it to be easily integrated into existing treatment lines, adapting to the needs of the plant where the machine is to operate and offering an excellent combination of power, precision, and operational flexibility.

.jpg?width=2000&height=1124&name=20250311_093319%20(1).jpg)

The recovery and treatment of ferrous waste

CAMEC designs and builds complete lines for the recovery of metals and scrap iron, designed to process heterogeneous masses of material and precisely separate the different types of metal for re-melting.

The treatment process is divided into automated phases:

- Primary Shredding – The scrap is loaded into a hopper and its size is reduced using the CR2A rotary shear, equipped with a double independent shaft and wear-resistant steel blades. This machine is designed to process large-sized scrap and mixed materials, ensuring operational continuity and low maintenance.

- Secondary Grinding – The material is further crushed to eliminate any non-shreddable components and to separate the light fractions thanks to the CAMEC MV 2000 vertical hammer mill.

- Separation – Magnetic and Eddy Current Separator (ECS) systems allow for the isolation of iron, copper, aluminum, and non-ferrous alloys.

- Screening and granulometric control – The separated fractions are uniformed to obtain a final product ready to be reintroduced into the market.

All CAMEC plants for the treatment of ferrous metals are modular and scalable, and can be sized according to production needs. Furthermore, they are equipped with multi-stage ventilation, suction, and filtration systems that reduce dust and odors, improving air quality and workplace safety.

Thanks to these features, CAMEC lines can adapt to any context: from small collection centers to large industrial metal recovery plants.

CAMEC's customized technological solutions for safety and sustainability

The experience gained by CAMEC in the waste treatment and recovery sector translates into the development of technologically advanced machines and plants, capable of combining engineering innovation, operational safety, and environmental sustainability. All projects are custom-developed by our team of experts, and this approach allows us to personalize every technical detail based on the specific needs of our clients.

Furthermore, CAMEC plants can be integrated with control systems in line with the principles of Industry 4.0, which enable digital process management, remote supervision, and predictive maintenance, thus ensuring efficiency, traceability, and operational continuity, maximizing plant performance and minimizing the risks of malfunction and machine downtime.

The CAMEC team accompanies each client through all phases of machine or plant design and implementation, from preliminary analysis to mechanical and electrical design, from construction and testing at the client's site, also handling after-sales support and staff training. In this way, we are able to develop high-performance, safe, reliable, and fully compliant turnkey plants with European regulations, which help any entity make waste treatment a strategic, efficient, and sustainable process, where technology serves the environment and productivity.

To receive a personalized consultation, ask our technicians questions, or learn more about the features of our plants, contact the CAMEC team: we are at your disposal to identify tailor-made solutions for your needs, capable of combining efficiency and sustainability.

Tell us about your project

We supply the best technical solutions for your requirements