Aluminium profile recycling

Aluminium is a material with a potentially infinite lifespan. Disposal of aluminium profile waste yields iron, aluminium and inert materials. Aluminium recycling starts with volumetric reduction, followed by shredding of the material. The final stage is the separation of ferrous and non-ferrous metals and inert components such as plastic and rubber. In the end, the aluminium is returned to the smelter and becomes a new quality material, used primarily in the construction industry.

Single-shaft shredder GSR480

GSR480 with 480 mm rotor is a single-shaft shredder with radial pusher and electric motor drive. These shredders are equipped with a grid to allow uniform piece size at outfeed.

- High shredding surface area

- Compact dimensions

- Bearings amply separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the compartment

- Screen maintenance

Single-shaft shredder GS650

GS650 with 650 mm rotor is a single-shaft shredder with radial pusher and electric motor drive able to guarantee high hourly throughput.

- Arc welded monobloc structure for elevated robustness

- Large shredding surface area and the maximum reliability

- Bearings separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the service compartment and the screen

Single-shaft shredder GS900

The high-powered GS900 shredder is a top-of-the range single-shaft machine with radial pusher, equipped with electric motor drive and able to guarantee high hourly throughput.

- Arc welded monobloc structure for elevated robustness

- Large shredding surface area

- Bearings amply separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the service compartment and the screen

Single-shaft shredder GL650

GL650 with 650 mm rotor is a single-shaft shredder with radial pusher and hydraulic motor drive able to guarantee very high hourly throughput.

- Arc welded monobloc structure for elevated robustness

- Large shredding surface area

- Bearings amply separated from the shredding zone

- Planetary gear reducers

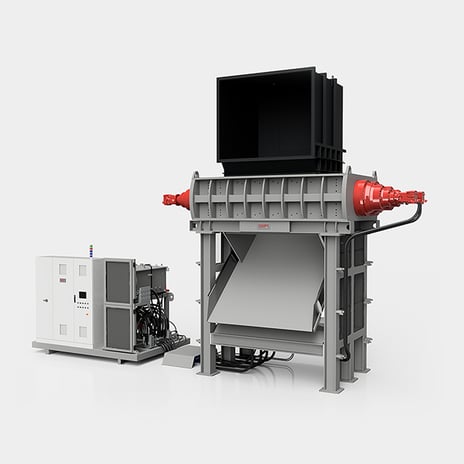

Rotary Shears - CR2A645

Model CR2A645 is specifically designed for heavy duty work on high wear materials. Ideal for volumetric reduction and coarse shredding of steel waste, ferrous scrap, or material in high-density bales.

- Shredder with two independent working shafts to reduce the rpm

- Easy maintenance cutting chamber with various blade configurations

- Wear-resistant cutting tools

- Customizable base and hopper for material loading and discharge

- Control panel with PLC to manage the machine, integration with other machines, the emergency circuit and safety of the mechanical parts