Mobile shredders are machines for waste treatment characterized by the presence of special movement systems that allow them to be easily moved, facilitating the loading of waste and reducing treatment times, without affecting their performance in terms of efficiency.

The main advantage associated with the use of a mobile shredder is precisely the possibility of bringing the machine closer to the waste to be treated: to make this possible, shredders are equipped with special movement systems that allow them to be easily moved within the industrial plant, waste treatment center or ecological island where they are operational.

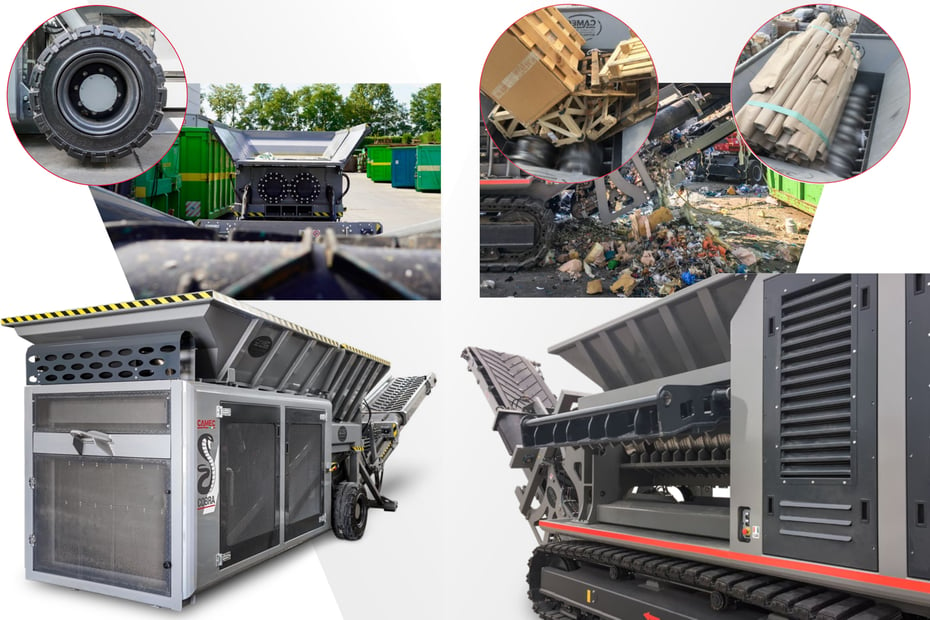

Movement systems: mobile shredders with tracks or wheels

Mobile shredders can be equipped with two types of structures: track-laying or wheeled.

In the case of a track-laying structure, the shredder is designed to be easily loaded onto a truck equipped with a special hook, allowing it to move freely within the work area and bring the shredder to the most favorable point. Once positioned, the shredder can be easily unloaded from the truck and used, and then re-moved as needed. This way, the space required is minimal and the efficiency of the work is maximized, reducing the time for loading waste and facilitating the work of operators, especially in the case of bulky waste.

A mobile shredder with tracks is instead completely self-propelled, and does not need to be installed on special supports to be moved within the work area. The presence of tracks allows the machine to move autonomously within the plant, without the need for trucks or trailers equipped with a hook.

It is important to remember that the movement systems do not affect the performance of the shredders, which are equipped with the same blades and rotors as fixed shredders. The cutting capacity, versatility, and efficiency are therefore the same as a fixed shredder, but with numerous advantages from an organizational and logistical point of view.

CAMEC's mobile shredders with tracks and wheels

CAMEC's line of mobile shredders includes both track-laying and wheeled models. Both movement systems are absolutely valid and capable of guaranteeing excellent performance, and the choice of which solution to prefer depends on many factors, such as available space, the type of waste to be treated, the frequency of use and so on.

Depending on customer preferences, CAMEC has therefore developed:

- Mobile shredder DRM 475: this shredder can be supplied in wheeled or track-laying version, and is equipped with hydraulic lowering wheels that facilitate its positioning in the area where it is to be used. The shredder has two rotors, each consisting of a central cylindrical shaft on which the blades are mounted, and is also equipped with a screen that allows the particle size of the output material to be regulated and prevents the passage of elongated waste that has not been shredded.

- Mobile shredder DRM 650: this shredder is available only in track-laying version and is equipped with a slow-rotating dual-shaft. It is ideal for the treatment of bulky waste, solid urban waste, paper, wood, and many other materials, and can be equipped with a range of accessories, such as the selection grate that allows the particle size of the output material to be controlled.

If you want to learn more about the potential of mobile shredders and are interested in a consultation to help you choose between track-laying and wheeled models, contact us now! We will present you with the offers in our catalog and study with you the solution that best suits your needs.