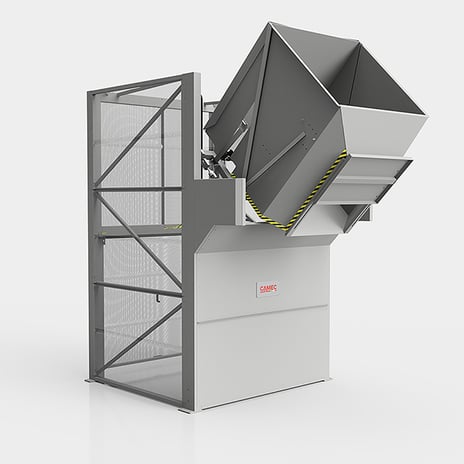

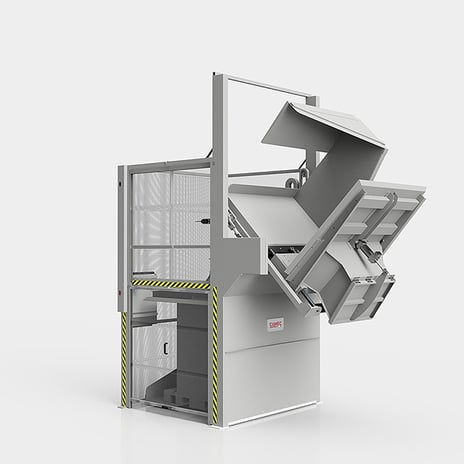

Cover with Pneumatic Actuator

A cover that is partly fixed and partly hinged, with the movable part of the cover controlled by a pneumatic-hydraulic actuator, which can retain the weight of the material during tipping until the actuator opening command.

Description

The pneumatic actuator uses air pressure to generate the force required to retain the load. This solution enables precise control over the opening and closing of the cover during the entire process.

Operators can activate the pneumatic actuator via an automatic or manual work cycle.

This system offers numerous advantages: the pneumatic actuator’s ability to retain the weight of the material reduces the risk of accidental falls or spills during tipping, while the spill cycle, which can be modified by the operator, allows for optimised product dosing.

Technical specifications

- Electric-pneumatic operation.

- Chain lifting transmission.

- Bin locking grippers.

- Bin locking bar.

- Pneumatic valve for bin locking.

- Door retainer timed micron.

- Pneumatic-electric safety valve.

- Air connection: 90° connection for Rilsan hose diam. 8.