Bulk aluminium recycling

Camec offers complete treatment of aluminium, both in bulk form and in compacted bales. Our production line is carefully designed to optimise the yield of a high-density end product. We therefore guarantee a highly efficient and sustainable aluminium treatment process.

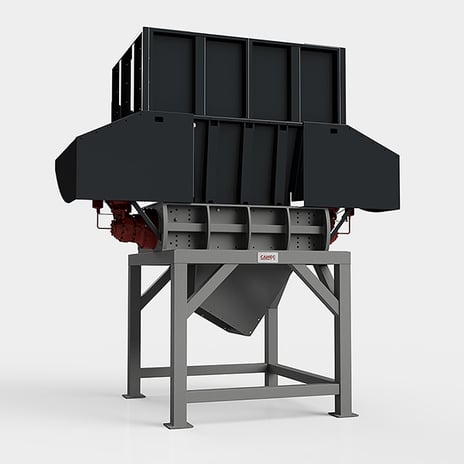

Single-shaft shredder GSR480

GSR480 with 480 mm rotor is a single-shaft shredder with radial pusher and electric motor drive. These shredders are equipped with a grid to allow uniform piece size at outfeed.

- High shredding surface area

- Compact dimensions

- Bearings amply separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the compartment

- Screen maintenance

Single-shaft shredder GS650

GS650 with 650 mm rotor is a single-shaft shredder with radial pusher and electric motor drive able to guarantee high hourly throughput.

- Arc welded monobloc structure for elevated robustness

- Large shredding surface area and the maximum reliability

- Bearings separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the service compartment and the screen

Single-shaft shredder GS900

The high-powered GS900 shredder is a top-of-the range single-shaft machine with radial pusher, equipped with electric motor drive and able to guarantee high hourly throughput.

- Arc welded monobloc structure for elevated robustness

- Large shredding surface area

- Bearings amply separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the service compartment and the screen

Single-shaft shredder GL650

GL650 with 650 mm rotor is a single-shaft shredder with radial pusher and hydraulic motor drive able to guarantee very high hourly throughput.

- Arc welded monobloc structure for elevated robustness

- Large shredding surface area

- Bearings amply separated from the shredding zone

- Planetary gear reducers

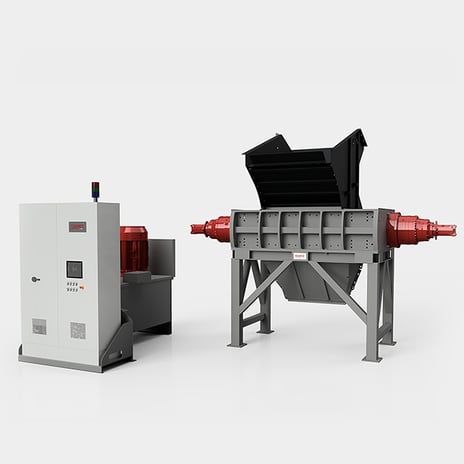

Two-shaft shredder TR2A200

TR2A200 is the most compact shredder in the TR2A series.

Two-shaft shredders are designed for volumetric reduction and coarse shredding of the material.

The machine has electric motor drive with planetary gear reducers and can be equipped with an inverter on request.

- Shredding section in arc welded fabricated steel (15 mm gauge plates)

- Bearings amply separated from the shredding zone

- 2 hexagonal section 80 mm shafts

- Independently driven rotors

- Shafts C/C distance of 200 mm

Two-shaft shredder TR2A300

TR2A300 is a medium-small shredder.

Electric motor drive, with planetary gear reducers and an inverter on request.

- Shredding section in arc welded fabricated steel

- Bearings amply separated from the shredding zone

- 2 hexagonal section 130 mm shafts

- Independently driven rotors

- Remote connection for assistance

Two-shaft shredder TR2A400

TR2A400 is a shredder that can be supplied in an electric or hydraulic version.

The very low consumption of this machine saves energy, while the special steel blades allow very long life cycles.

- Fabricated arc welded steel shredding section (30 mm gauge plates)

- Bearings amply separated from the shredding zone

- Independently driven rotors

- 2 hexagonal section 210 mm shafts

- Independently driven rotors

- Remote connection for assistance

Two-shaft shredder TR2A450

TR2A450 is a shredder suitable for heavy duty work cycles.

The generously sized frame is designed to withstand bending-twisting moments, also when shredding extremely tough materials.

- Fabricated arc welded steel shredding section (30 mm gauge plate)

- Bearings amply separated from the shredding zone

- 2 hexagonal section 200 mm shafts

- Independently driven rotors

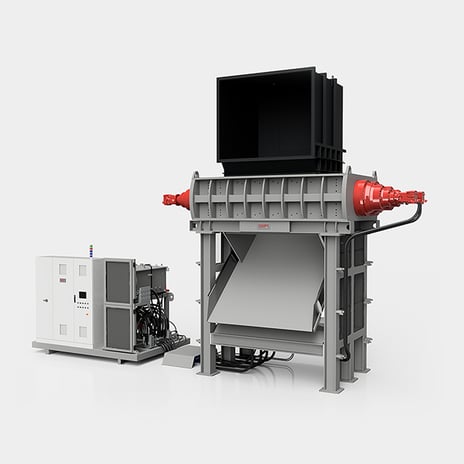

Two-shaft shredder TR2A520

TR2A520 is a top-of-the-range shredder suitable for heavy duty work cycles.

The generously sized frame is designed to withstand bending-twisting moments, also when shredding extremely tough materials, guaranteeing high performance levels.

- Bearings amply separated from the shredding zone

- 2 hexagonal section 240 mm shafts

- Independently driven rotors

Rotary Shears - CR2A645

Model CR2A645 is specifically designed for heavy duty work on high wear materials. Ideal for volumetric reduction and coarse shredding of steel waste, ferrous scrap, or material in high-density bales.

- Shredder with two independent working shafts to reduce the rpm

- Easy maintenance cutting chamber with various blade configurations

- Wear-resistant cutting tools

- Customizable base and hopper for material loading and discharge

- Control panel with PLC to manage the machine, integration with other machines, the emergency circuit and safety of the mechanical parts